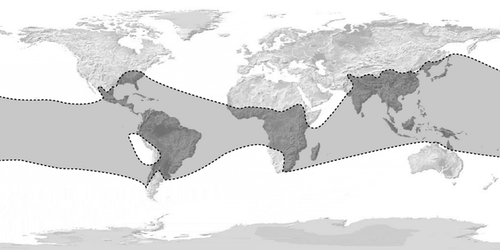

Occurrence of bamboo

There are over 1,250 different species of the bamboo plants, whose common geographical growing range is from 46° nothern latitude to 47° southern latitude.

We sell Tonkin bamboo which is imported from the highland of China.

Tonkin bamboo is robust and is considered to be called the 'natural carbon'. It is the favorite natural material used in the sport archery.

Application

For centuries bamboo has been used as building material for houses, furniture, floors etc.

Furthermore it is also a traditional material used for building bows (Yumi, Kyodo) and of course it is also an excellent material for arrows.

Structure

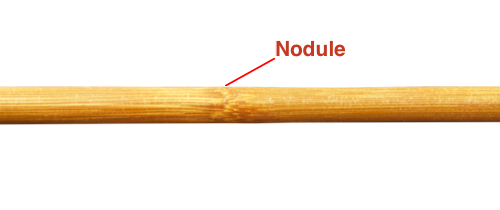

The culms are hollow and are divided into sections by the nodules. The nodules are not hollow. They are solid and don't bend.

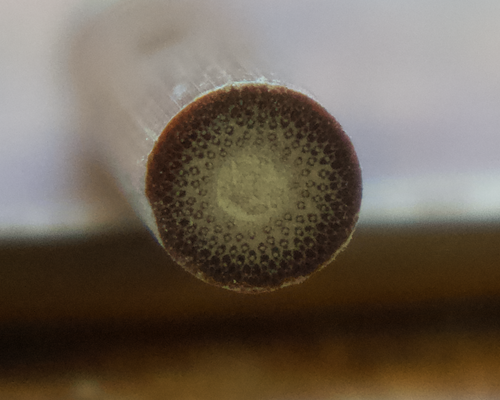

The outer layer of the culm is very hard and is held together by strong fibers. The fibers contain lignin which is also found in wood fibers. Lignin gives the fibers strength and stability. The fibers are covered with a natural smooth protective coating.

Inside the culm is the mark which does not essentially contribute to the stability.

Shaft Preparation

Bamboo shafts for arrow fabrication must first go through a slow drying process. The dried bamboo then gets aligned and the nodules get carefully sanded taking care that the fibers won't get cut. Finally the shafts get spined, sorted and wax-coated for protection. Bamboo shafts grow naturally with a conical form which corresponds to a natural taper in each individual shaft. The shafts grow consistantly but no two shafts are exactly alike.

Comparison to wood

In the process of machining wooden shafts the wood needs to get milled and sanded to get the round shape. Within this process the fibers of the wood are getting cut unavoidably which reduces the strength of the wooden shaft.

This kind of process is not used with bamboo shafts.

Bamboo has inherently a high content of silicic acid which contributes to its hardness and shape stability. It is exeedingly flexible and its strength is multiple times higher than wood. Due to its extremely dense cell structure bamboo has a very high degree of surface hardness with 4.0 HB (Brinell-hardness). Oak wood has 3.4 HB.

Spine

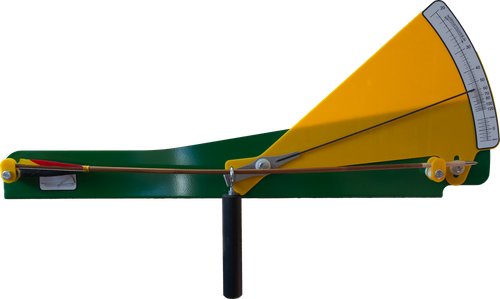

The spine is a measure to define the flexibility of a shaft on the basis of a shaft length of 28". The distance of the support points is 26".

The test weight is two english pounds (0.908kg). The deflection is being measured.

It tells how much power is needed to bend the shaft. The more the deflection the higher the flexibility the lower the spine.

Determination of the needed spine for wooden shafts

To choose the 'right' spine for the shaft, a couple of parameters have to be taken into consideration:

- The type of bow (Longbow English yew, Longbow Hickory, Primitive bow, Recurve, Mounted Archery etc.).

- Arrow shelf of the bow (small, center shot, bigger, for Reflex, Deflex, Recurve).

- Draw length (smaller spine for short draw length, higher spine for longer draw length).

- Weight of the point (higher than 125grain higher spine, less than 125grain less spine).

- Arrow diameter.

- Total weight of arrow.

It is easy to realize that there is no rule of thumb to calculate the right spine empircally. Only an approximated value can be assumed.

Spine for bamboo shafts

To determine the spine for bamboo shafts there are even more parameters to add:

- Number of nodules.

- Relation of starting diameter to ending diameter of the shaft. This should be the same for all arrows.

When you finally come up with a spine after having taken all of these parameters into your consideration then you have 'assumed' a measure for the static spine (theory). Remember the theory-practice-relationship.

All this can be very confusing.

Best practice shows that there are three main parameters when selecting bamboo shafts:

- Make sure the shafts have the same weight

- Have the same amounts of nodules on each shaft (Nodules are stiff and don't bend).

- Shelf on your bow (Yes/No).

The deeper the shelf towards the center of the bow (closer to center shot) the spine matters less and does not influence the straight flight of the arrow that much. In this case the spine of the arrow corresponds to the draw weight of the bow.

Within a spine range of e.g. #40-45 there can be a variance of the shaft weight up to 10 grams which is 150 grain. Therefore it is very important to get a selection of shafts with the same weight. We offer weight groups of shafts which are weighed +-0,5 grams.

The bamboo shafts are 33“ (84cm) long. Having a draw length of 28“ there are 5“ (12,7 cm) to find a 28“ 'window' out of the total length of 33“. Following this method it it easy to select a group of shafts with the same diameter within a spine range.